Division 32 - Unit Pavers

- This information provides guidelines for brick and concrete unit pavers, including base and drainage requirements and materials. Temporary facilities and controls are covered in other parts of these standards or are available from the WWU project representative.

- WWU project representative, Public Safety Office, and Environmental Health and Safety Office shall approve selection of materials, means, and methods. Unless otherwise approved, design intent requires means and methods that provide minimal disruption to adjacent building activities and operations.

- When working on or adjacent to occupied buildings, require means and methods that protect occupants from exposure to noise, dust, traffic, and other hazards.

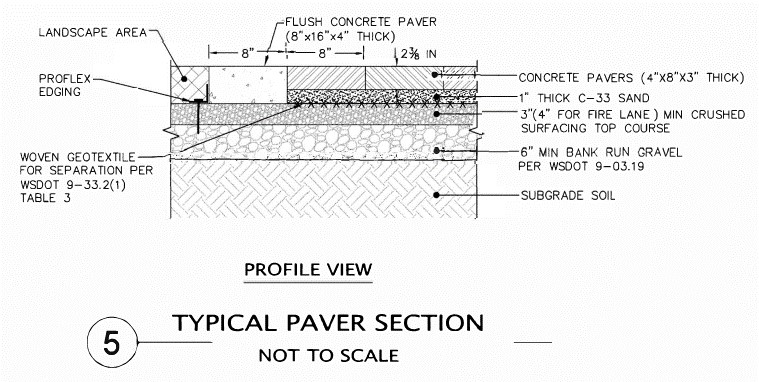

- Settlement and inadequate depth of setting beds are two of the most common reasons for problems on campus. Improper preparation of subgrade continues to be a problem in areas over soft soil conditions, which results in uneven transitions to walkways or building entrances. Settlement of base course and setting bed shall be at least partially controlled by careful detailing.

- Require edge of walkways to be contained within a secure edge detail.

- Crushed rock, sand bed, and brick must be confined on all four sides. Following recommended edge details on campus may include:

- 4" x 8" x 16" solid concrete block

- Cast-in-place concrete curb either flush with grade or raised

- DO NOT USE treated wood timbers of any kind.

- Detail transitions to dissimilar materials.

- Require positive subgrade drainage by slope and drainage system.

- Design and install the sub-base for heavy vehicular use.

- Specification shall call for compaction testing of subgrade, base course, and sand setting bed, at 90% to 95% compaction.

- For extensive filling of subgrade, keep lifts of fill to 6" or less class B pit run, and test each lift for compaction. Provide positive drainage (perforated drain in drain rock and filter fabric).

- Use a geotextile filter fabric over the compacted subgrade. Turn up at perimeter to contain the setting bed material:

- a. Mirafi 140N or

- b. Fibertex 150, or approved equivalent.

- Typical installations: 8” of crushed rock base course, placed in two equal lifts and compacted, with a 4” perforated drainpipe. The perforated drainpipe shall be at the lowest portion of any slope and shall be taken to a storm drain. Lay perforated drain in pea gravel below the walkway rather than in crushed material and wrap in filter fabric. Lay brick rough-side up for greater slip-resistance.

- Concrete pavers use the same base course and setting bed as brick pavers. Adjust depth as needed.

- The Western standard concrete paver is 8" x 4" x 3".

- Nonstandard pavers:

- 8" x 4" x 3" brick pavers.

- 8" x 4" x 2¼" brick pavers.

- 8" x 4" x 1½" brick pavers.

- 12" x 5½" concrete pavers patio at the south side of Ridgeway Commons.

- Concrete/Hydroslab pavers:

- 24" x 24" x 1⅝", 22 lb./sq. ft weight concrete paving system (ex: PA Plaza).

- Paver support with integral corner pedestals of standard SBR rubber, high-density polyethylene or polyurethane.

- Supports include fixed height pedestals, shims and spacer tabs for joint space of ⅛" typical.

- Color: brick red or manufacturer’s equal color name.

- 24" x 24" x 1⅝", 22 lb./sq. ft weight concrete paving system (ex: PA Plaza).

Latest update

2023-11-06